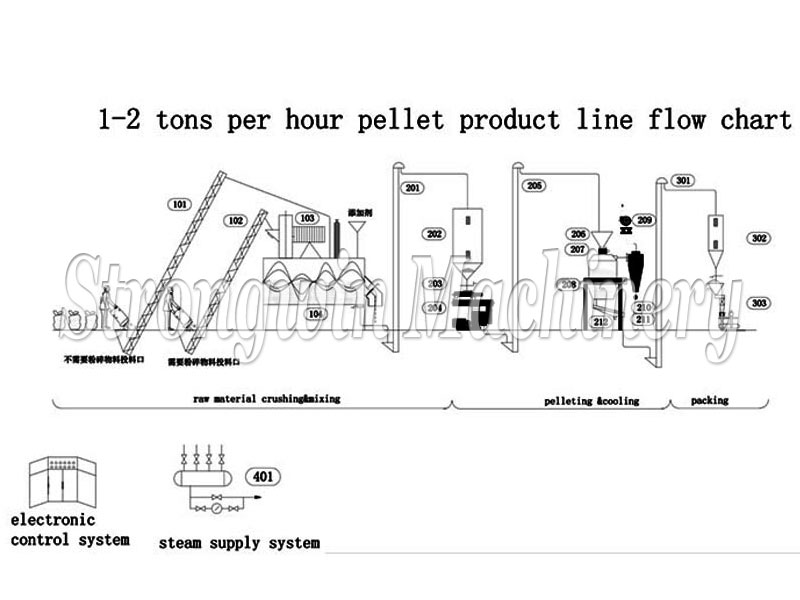

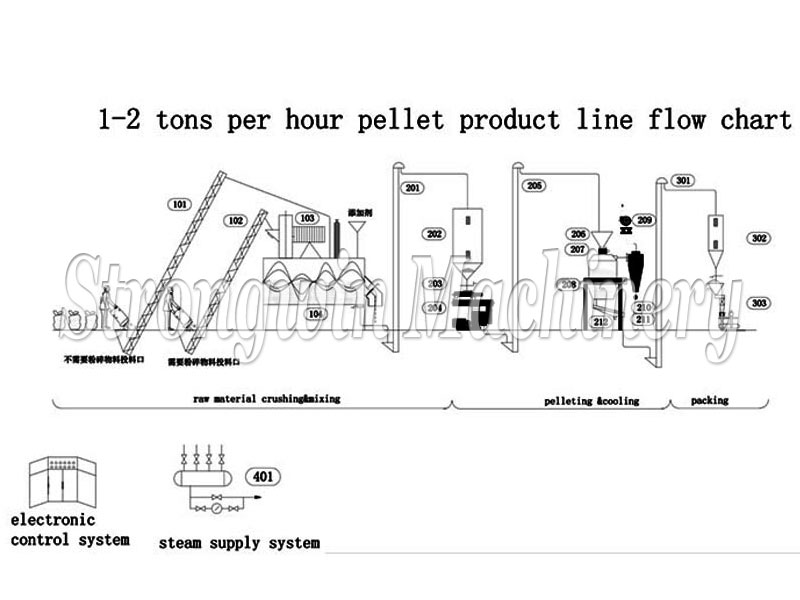

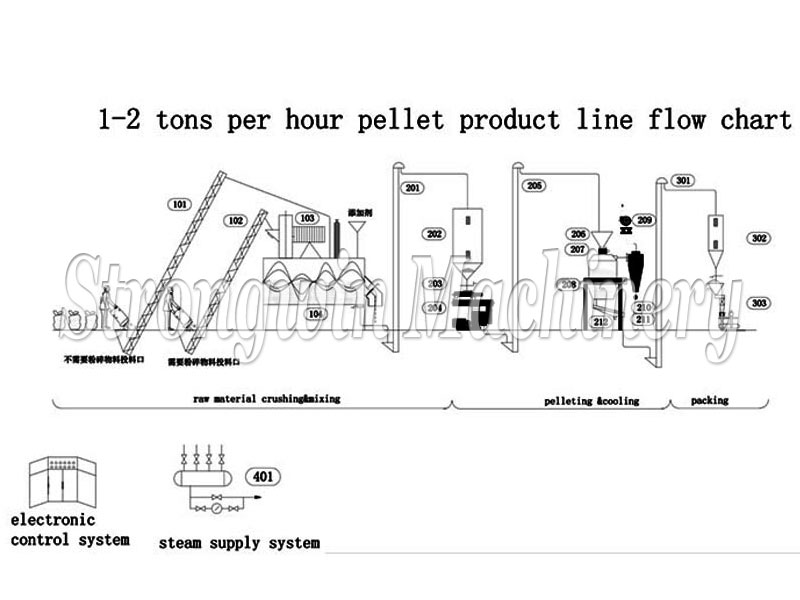

Hammer Crusher & Mixer: Adopts regrinding crushing technology, widens the screen in 360° the materials can be crushed on average. The coefficient of variation is less than 5%, the mixing time is 5 minutes, then the materials can be discharged from one side. There is no dead corner when mixing, and this machine is easy to maintain.

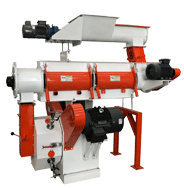

Feed Pellet Machine: Good quality ting die, stainless steel conditioner, reliable working, adopts double motors driving, over-loading protection.

Feed Pellet Cooling & Screening Process: It can decrease the temperature and moisture of the feed pellets, preparing for the following processes. After the screening, you can get qualified feed pellets without fine powder.

Packing Process: Automatic weighing and packing machine can weigh and pack the pellets automatically with high accuracy.

Application

For making cattle, geese, pig, duck, chicken, sheep, rabbit, and other animals, livestock, and poultry feed.Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.

After installation and adjustment, we will train our customer's work how to operate;

Training worker how to maintain and protect

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintains)

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.