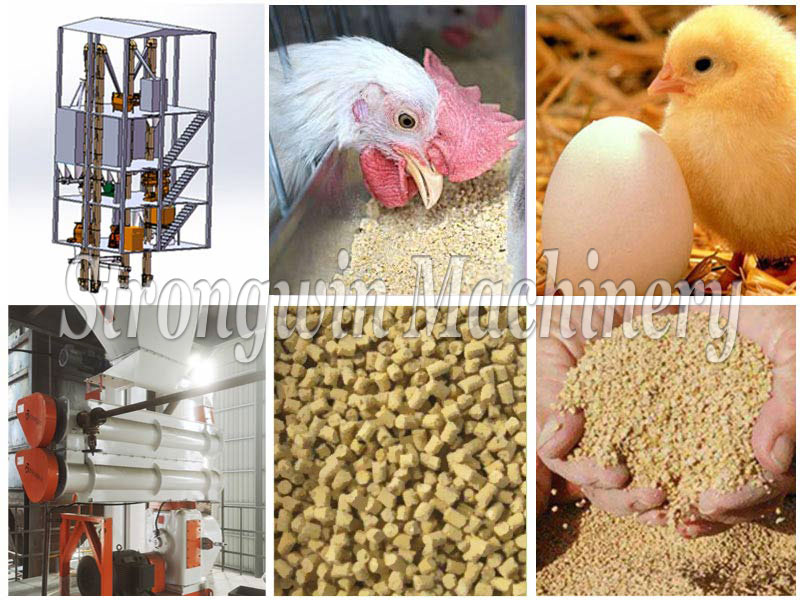

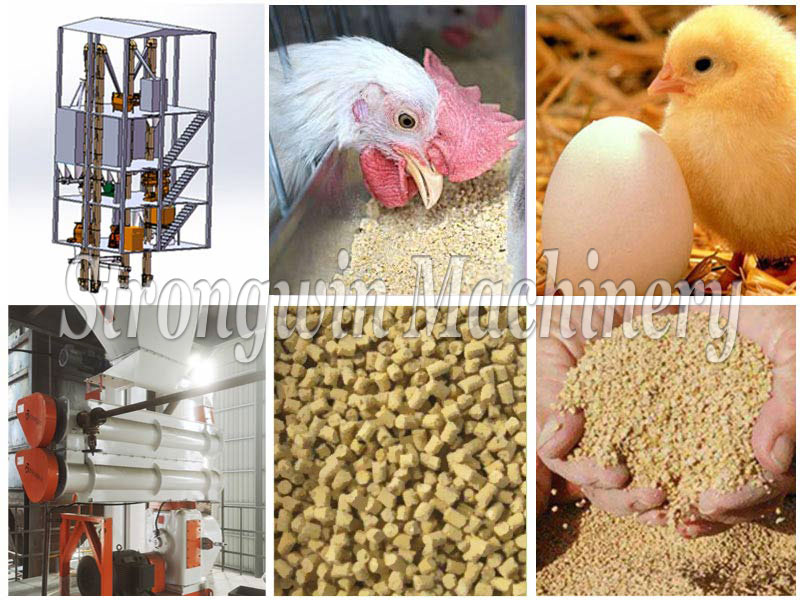

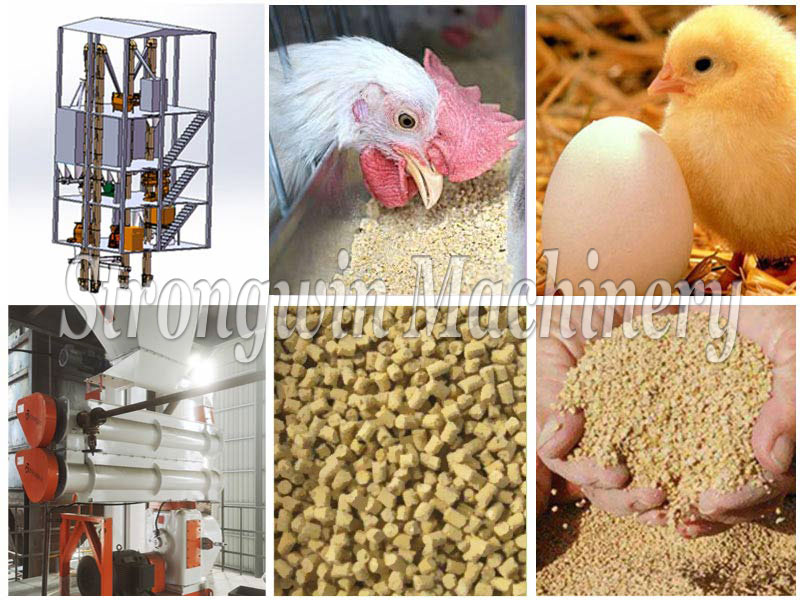

1.Raw materials for chicken feed pelletizing processing

Materials for feed can be soybeans, soybean meal, alfalfa, corn, fish meal, amino acid, fuel meal, additives, whey powder, oil, meat and bone meal, corn, sweet sorghum, etc.

2. Chicken Feed Manufacturing Grinding process: Chicken Feed Hammer Mill

Chicken feed hammer mill is suitable to grind raw materials into powder with the optimal size for the best pelletizing effect.

3. Feed Mixing process: Chicken Feed Mixer

By adopting a chicken feed mixer, various ingredients can be blended sufficiently to ensure every bite of finished feed pellets can have balanced nutrients.

4. Feed Pelletizing Process: Ring Die Chicken Feed Pellet Mill

The chicken feed pellet mill is the main equipment of the whole feed production line. Compared with a flat die feed pellet mill, a ring die chicken feed pelletizer is more efficient and suitable for high-quality chicken feed pellets production in large farms or feed pellets factories. Built-in steam collection conditioner can mix and cook materials fully and uniformly to meet special needs and ensure the high quality of final chicken feed pellets.

5. Feed Pellet Crushing Process: Chicks Feed Pellets Crumbler

Different poultry, livestock, or aquatic feed pellets are of different sizes. Some big ones should be crushed into small ones. Roll-type feed pellet crumbler is just the equipment for feed pellet crushing. Double-roll feed pellet crumbler is suitable for crushing poultry feed, such as chicken feed, duck feed, goose feed, etc. Three-roll feed pellet crumbler is suitable to crush aquatic feed including fish feed and shrimp feed etc.

6. Feed Pellet Cooling Process: Chicks Feed Pellets Cooler

After this process, you can get finished chicken feed pellets with rich nutrition, good palatability, and high digestibility. Chicken feed pellets cooler and packing machine are available for your choice to get top feed pellets making experience. Moreover, to cater to the special requirements of our clients, we can also customize different capacity poultry feed pellets production lines.

The machine can make pellets for poultry, chicken, duck, bird, and so on.

mainly sinking pellets, because the density of the pellets is big, if you want to make floating feed, so you need to buy one more extruder.

After installation and adjustment,we will train our customers work how to operate;

Training worker how to maintain and protect

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintains)

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.